Wally / Montana

(You can send a personal message to "Wally / Montana" at the Stovebolt Page but you have to join first.)

My 1948 Chevrolet 3/4-ton high above the Missoula Valley

I have been a fan of old Chevrolets since 1962 when I bought my first car - a '51 two-door Deluxe - for $60.

Four years later, that old Chevy with its splash-oiling 216 engine carried us and a U-Haul trailer 1250 miles from western Washington

to southeast Wyoming, crossing the Continental Divide several times through Yellowstone while loaded to the gills. We had a contest

to see which family member could guess our miles per gallon.....of oil!

In 1964, while I still had the '51, I bought a '39 Chevrolet four-door Master Deluxe car for $20. I figured its full tank of gas made the net cost $15! It quit running and needed some work so

starting in 1966...after priming and painting...it was stored at seven places - with in-laws, mostly - while we moved from Washington to Wyoming to Florida to Georgia to Wisconsin and, finally, to Montana.

I ran out of in-laws who would keep the darn thing and I didn't want new ones (I love my wife!!),

so I sold the '39 in Washington in 1992 for $1500 and bought the '48 truck in Montana for $600.

The body style of the '48 Chevrolet truck is called Advance Design. Mine has the deluxe stainless steel window trim and

chrome grill. Windows 4 and 5 on the corners - originally advertised as Nu Vue windows - coupled with a cab fairly far

off the ground make for excellent visibility in all directions.

I think yellow house paint was used to cover the original Forester Green. There was a little surface rust on the fenders so

I painted them with black Rustoleum temporarily. It is funny how long "temporary" can last!

The body style of the '48 Chevrolet truck is called Advance Design. Mine has the deluxe stainless steel window trim and

chrome grill. Windows 4 and 5 on the corners - originally advertised as Nu Vue windows - coupled with a cab fairly far

off the ground make for excellent visibility in all directions.

I think yellow house paint was used to cover the original Forester Green. There was a little surface rust on the fenders so

I painted them with black Rustoleum temporarily. It is funny how long "temporary" can last!

The running boards indicated it originally had the 8 foot box but some previous owner made his own flatbed for it.

It had the knob in the cab for a PTO - a power take-off - but, sadly, the unit was not bolted to the 4-speed transmission.

I've always wanted to hook up a big ice cream maker to a power take-off!

I quickly rebuilt the master and wheel cylinders and installed new brake shoes but the engine - a '53 full-pressure 235

(from a car with Powerglide) - was in great shape and burned no oil (although it did leak some). I cut a hole in the flatbed

and recessed the spare tire into it.

The Carter W-1 carb worked fine after a rebuild but I replaced the oil-bath air cleaner with a Fram. I raided the kitchen for a cake pan to top it off. Gear lube leaked out the torque tube half of the drive line - what a perfect place to strap a sauce pan! I won't say where I used a cookie pan!

I had the seat rebuilt and my wife fine-tuned some new Saddleman seat covers. That completed the first stage of

restoration - I could drive it without getting dirty!

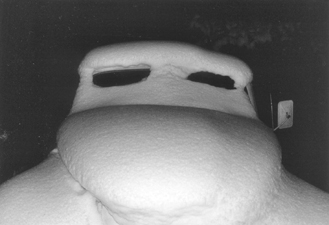

The '48 became my daily driver. I worried some about the liquid deicer used on our city streets in winter

but - supposedly - it contains corrosion inhibitors and I rinse the truck frequently whenever the deicer is being used.

When I take it out of town, I hang a blaze orange farmer's triangle on the back since my comfortable top speed is 40-45 MPH.

After 10 years of daily driving, I decided to adjust the valves - maintenance that I had never done.

I noticed a drop of "green water" on the head. Yep, magnafluxing showed a crack between cylinders four and five.

With the head off, I found a smooth indentation up and down the number one cylinder wall.

Yep, a broken ring.

I talked to an engine fellow about rebuilding the 235 but he had a '61 full-pressure, full-flow 261 which was indeed better. It was not just the greater horsepower; the oiling system was much better. I found an "848" head (casting # 3836848) at the junk yard and found a second one later for a spare. These heads - from later 235's - have slightly smaller combustion chambers which give a little higher compression ratio and horsepower than the original head for the 261.

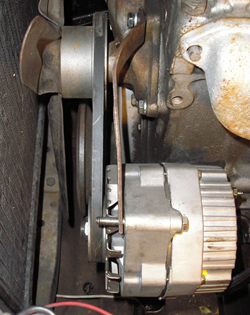

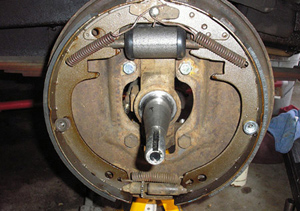

The rebuilt engine - the last in the 216-235-261 series of straight Stovebolt sixes - dropped in and bolted up with very few problems. I found a Rochester Monojet carburetor which was needed for the new intake manifold at the junk yard. I also swapped the original 4.57 rear end "pumpkin" for a 4.10 and completely rebuilt the brake system including new lines and a dual reservoir master cylinder.

In March, 2004, I started up the 261 for the first time. Mrs. Wally was there, of course, but she held a fire extinguisher!

Smart girl. Twenty minutes at 2000 RPM was recommended for seating the cam shaft. Was I ever happy!!!!

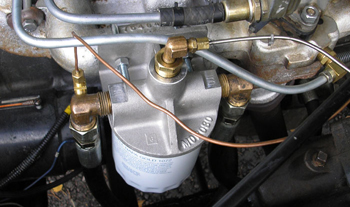

I later changed to a Moroso adapter for a spin-on oil filter.

I had two oil pressure gauges - before and after the filter - for a while.

I wanted some info about a pressure drop across the filter when started

but the response time on the first gauge was much slower than the other.

I must thank my wife for her support during the project - even letting me co-mingle items in the dish drainer.

A Carter YF 2100S carb - which I'll swap for the Rochester Monojet later - is shown below.

|

12-Volt electric wiper motor. I called the old vacuum system "intermittent wipers." Sometimes they worked, sometimes they didn't.

|

6-volt heater fan motor and give it two speeds.

|

|

The old radio face plugs up the original holes.

|

on the front with Bendix brakes from a '57 1-ton.

|

Steve was a great help in my project. We got in contact on the Internet via the

Stovebolt Forum

and found our offices at work were only 150 yards from one another! Mine hangs a little low and to the left because of

a spring problem.

Later, Glenn Slay and I got in touch when he saw on the Stovebolt Page that I lived in Missoula.

Small world again! Here is Glenn's very nice '54 1/2-ton. (Glenn has since sold hjis '54.)

We meet with Glenn periodically to check Tor's progress on his '54. He'll be pulling the engine for a rebuild

during winter 2014-15. That is a handcrafted, heavy duty gas tank/tool box in the back!